How does the male ball valve design enable smooth and effortless on/off operation?

The male ball valve design is a key characteristic...

MORE >>

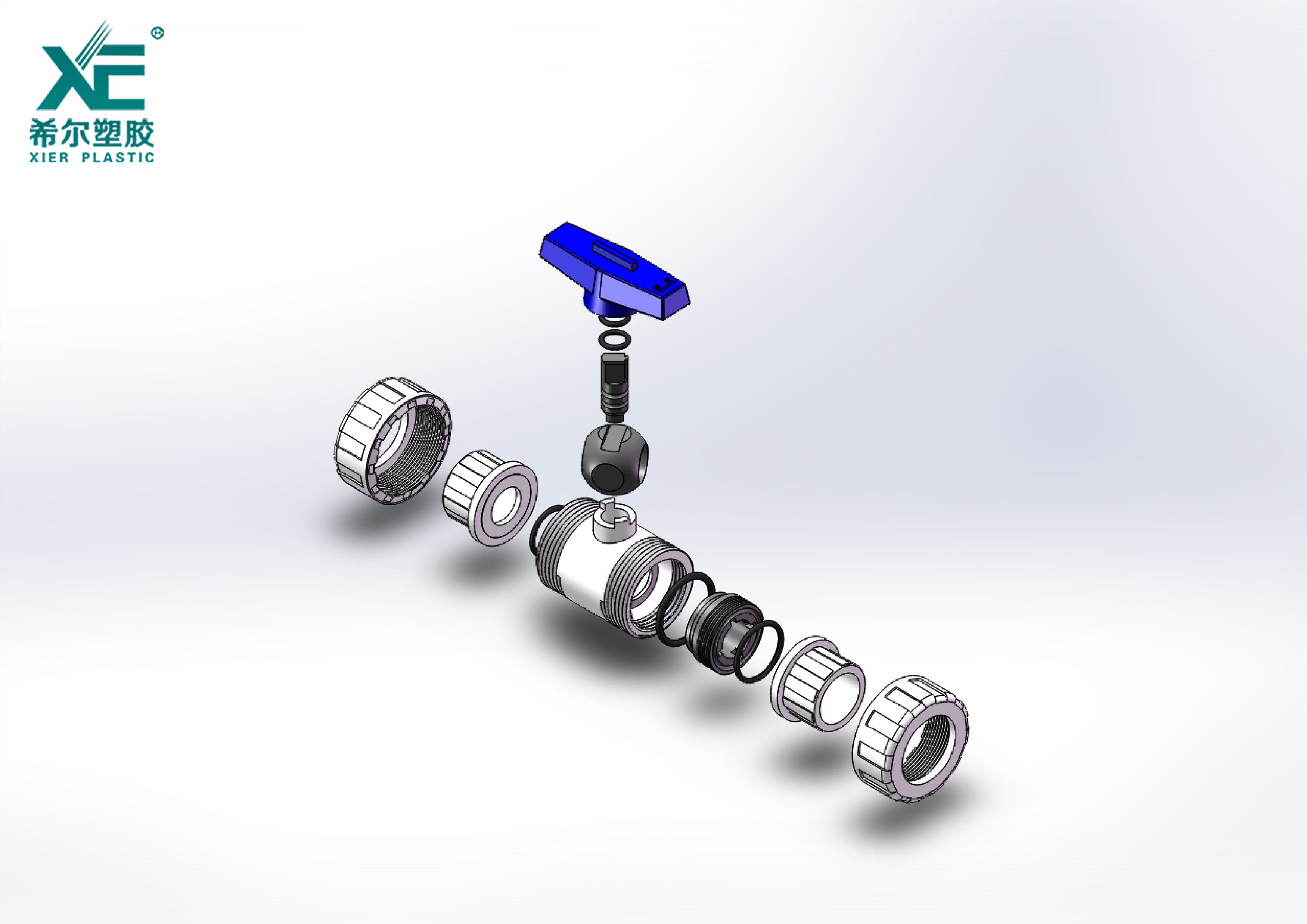

Ball valves are a type of quarter-turn valve that use a […]

Ball valves are a type of quarter-turn valve that use a ball-shaped disc to control the flow of fluids through a pipe or pipeline. They are commonly used in various industries, including oil and gas, water treatment, chemical, pharmaceutical, and manufacturing. Ball valves offer several advantages over other types of valves, making them a popular choice for many applications. In this article, we will explore the advantages of using a ball valve over other types of valves.

Excellent Flow Control:

One of the primary advantages of ball valves is their excellent flow control capabilities. The ball-shaped disc with a hole (bore) in the middle allows for smooth and unrestricted flow when the valve is in the fully open position. This full bore design minimizes pressure drop across the valve, making ball valves ideal for applications where low flow resistance is essential.

Quick Operation:

Ball valves are quarter-turn valves, meaning they can be opened or closed with just a 90-degree turn of the handle or lever. This quick and simple operation makes ball valves easy to use and allows for rapid response in emergency shutdown situations.

Tight Shut-Off:

Ball valves offer tight shut-off, ensuring that there is minimal leakage or seepage when the valve is closed. The ball-shaped disc creates a secure seal against the valve seat, effectively preventing the flow of fluid through the pipeline when the valve is in the closed position. This tight shut-off is particularly crucial in applications where preventing leakage is critical, such as in hazardous chemical processes or critical gas systems.

Durability and Longevity:

Ball valves are known for their durability and longevity. The ball-shaped disc and simple design result in fewer moving parts, reducing the likelihood of mechanical failure. Additionally, the majority of ball valves are made from robust materials, such as stainless steel or brass, which offer excellent corrosion resistance and can withstand harsh operating conditions.

Versatility:

Ball valves are highly versatile and suitable for various media, including liquids, gases, and slurries. They can handle a wide range of pressures and temperatures, making them suitable for both high-pressure and high-temperature applications. Moreover, ball valves are available in various sizes and configurations, making them adaptable to different pipe sizes and connection types.

Minimal Maintenance:

Due to their durable construction and minimal moving parts, ball valves require relatively low maintenance compared to other types of valves. Regular maintenance typically involves simple cleaning and inspection to ensure proper functioning. This reduced maintenance requirement can lead to cost savings and less downtime in industrial processes.

Bi-Directional Flow:

Unlike some other types of valves, ball valves offer bi-directional flow, meaning they can control the flow of fluids in both directions. This bi-directional flow capability adds to their versatility and makes them suitable for applications where flow direction may need to be changed or reversed.

Fire-Safe Design:

Some ball valves are designed to be fire-safe, making them suitable for use in applications where fire safety is critical. Fire-safe ball valves are designed to maintain their integrity and sealing capability even in high-temperature fire conditions, providing an added layer of protection in fire-prone environments.

Low Torque Requirement:

Ball valves typically require lower torque to operate compared to other types of valves, such as gate valves or globe valves. This lower torque requirement makes ball valves easier to operate, especially in large or high-pressure systems.

Cost-Effective:

Considering their durability, low maintenance needs, and excellent flow control capabilities, ball valves are often cost-effective solutions for various applications. While the initial cost may be slightly higher than some other types of valves, the long-term benefits in terms of performance and reduced maintenance costs make them an economical choice.

Ball valves offer numerous advantages over other types of valves, making them widely used in various industries. Their excellent flow control, quick operation, tight shut-off, and durability make them ideal for critical applications where precision and reliability are essential. The versatility of ball valves allows them to handle different media, pressures, and temperatures, while their low torque requirement and fire-safe designs further enhance their usability. Additionally, the minimal maintenance and cost-effectiveness of ball valves make them a practical choice for long-term installations. Overall, the advantages of using ball valves demonstrate why they are a preferred choice for flow control in a wide range of industrial and commercial applications.

The male ball valve design is a key characteristic...

MORE >>

In today's modern world, efficient and reliable wa...

MORE >>

Copyright ©All rights reserved:Zhejiang Xier Plastic Valve Lead Co.,LTD. PVC Ball Valves Manufacturers Technical support: HWAQ  浙公网安备 33060402001174号

浙公网安备 33060402001174号

English

English España

España عربي

عربي